injection molding companies

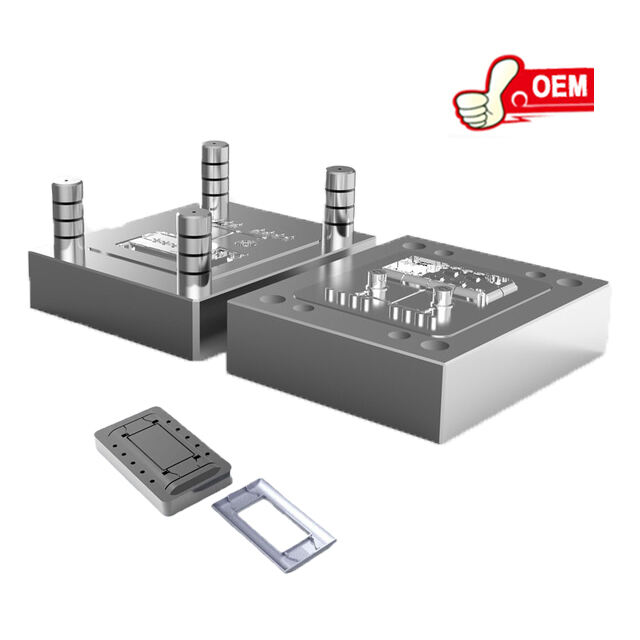

Injection molding companies are at the forefront of manufacturing, providing precision-formed plastic components for a myriad of industries. The main function of these companies is to design and produce high-quality plastic parts using the injection molding process, which involves melting plastic material and injecting it into a mold cavity where it cools and solidifies. Technological features include state-of-the-art machinery, computer-aided design (CAD), and sophisticated control systems that ensure precision and consistency in production. The applications of injection molding are vast, ranging from automotive parts and medical devices to consumer goods and electronics, making it an indispensable process in modern manufacturing.