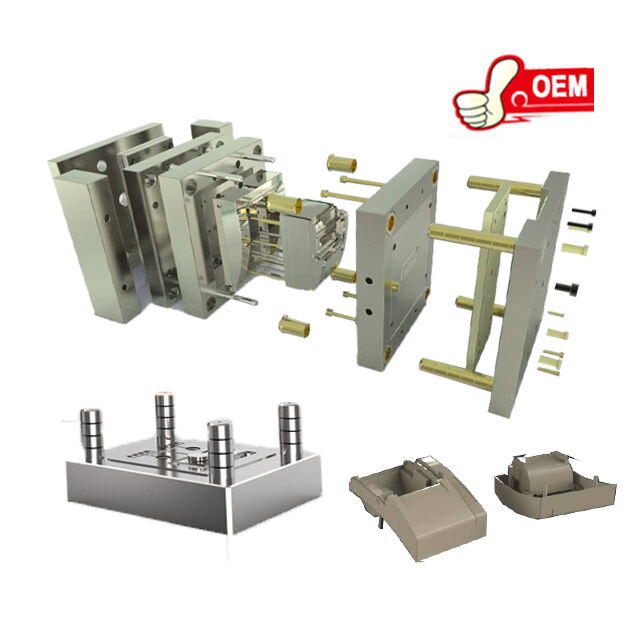

injection mold fabrication

Injection mold fabrication is a precision engineering process that involves creating molds used for producing plastic parts through injection molding. The main functions of these molds are to shape, form, and solidify molten plastic into the desired product. Technological features include intricate design work, high-precision machining, and the use of advanced materials that can withstand the high temperatures and pressures of the molding process. These molds are versatile, capable of producing a wide range of products from simple to complex geometries. Applications span various industries including automotive, medical, consumer goods, and electronics, where high-volume production with consistent quality is essential.