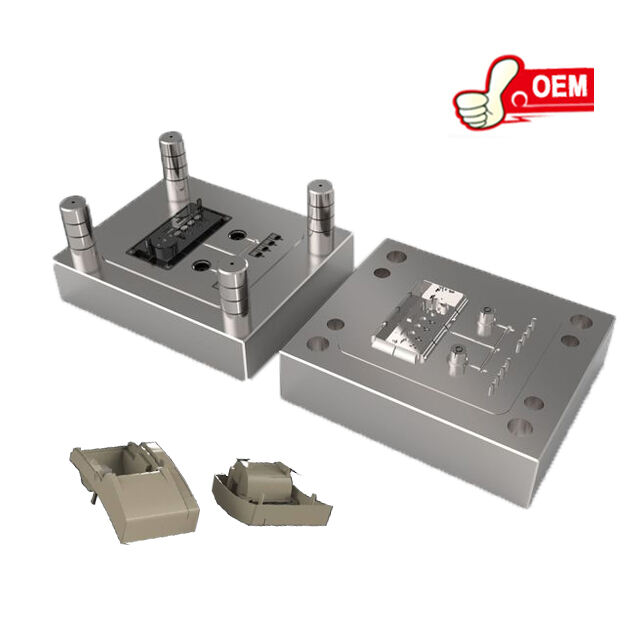

injection mold maker

The injection mold maker is a sophisticated piece of equipment designed for the precise manufacturing of plastic components through injection molding. It performs several main functions including mold design, material injection, cooling, and ejection. Technological features of the mold maker encompass high-precision engineering, automated controls, and advanced temperature regulation systems. These features ensure the production of intricate parts with tight tolerances and consistent quality. Applications span across various industries such as automotive, electronics, medical, and consumer goods, making it an indispensable tool in modern manufacturing.