two shot moulding

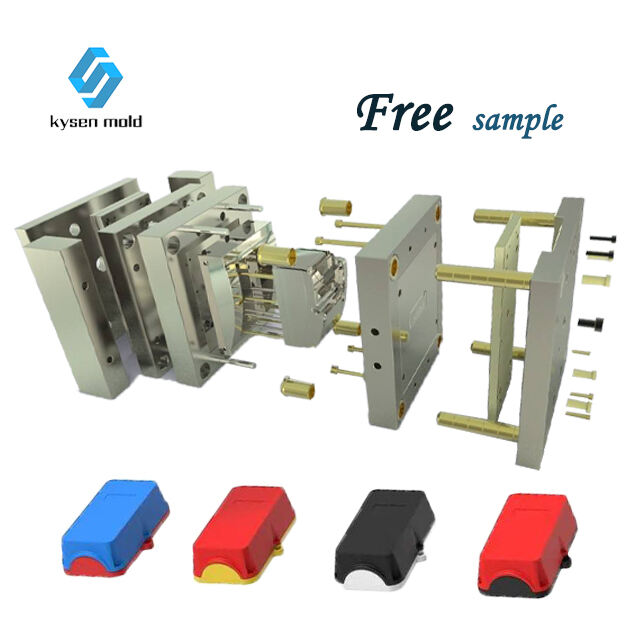

Two shot moulding is an innovative injection moulding process that involves the simultaneous use of two or more materials to produce a single part with multiple components or functionalities. The main function of two shot moulding is to create complex products that cannot be made using traditional single-material moulding methods. Technological features of this process include advanced machinery with multiple injection units, sophisticated control systems to manage the flow of different materials, and precise timing mechanisms to ensure proper material placement. This technique finds extensive applications across industries such as automotive, medical, electronics, and consumer goods, where complex, high-performance parts are required.