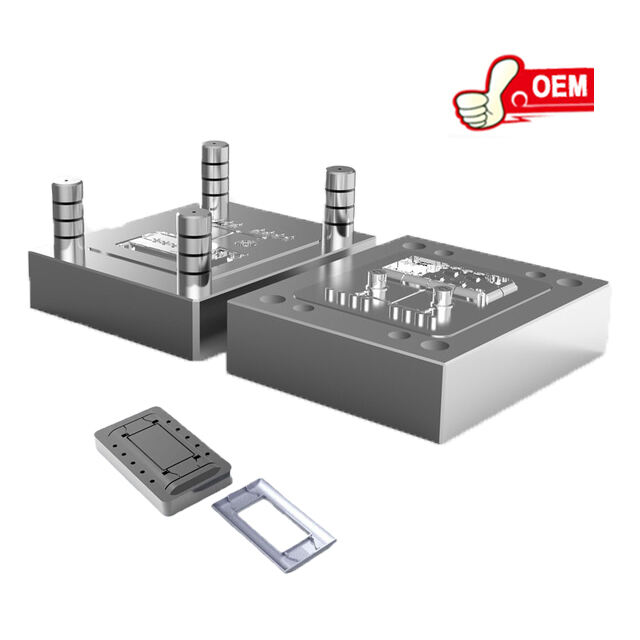

low cost injection molding

Low cost injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold to produce parts and products. Its main functions include shaping, forming, and fabricating components with high precision and consistency. Technological features of this process encompass the use of advanced molding machines, sophisticated mold designs, and automated systems, which ensure efficiency and reliability. The applications of low cost injection molding are extensive, ranging from automotive parts and consumer electronics to medical devices and household goods. Due to its cost-effectiveness, it is particularly popular among businesses seeking to produce high volumes of parts while maintaining quality and affordability.