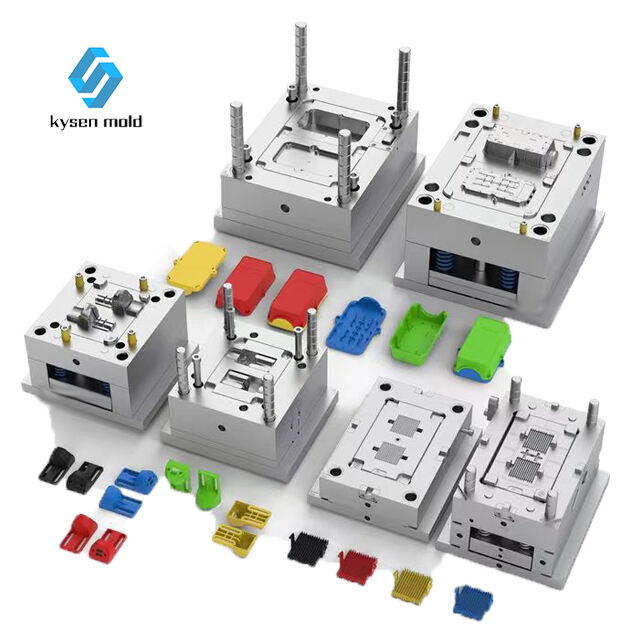

injection mould

The injection mould is a precision tool used in manufacturing to produce parts by injecting molten material into a mold cavity. Its main functions include shaping, cooling, and solidifying the material to form the desired product. Technological features of the injection mould include high precision, durability, and the ability to maintain consistent dimensions across multiple productions. These molds are equipped with heating and cooling systems to control the temperature of the material and the mold, ensuring high-quality products. Applications of the injection mould span various industries, such as automotive, electronics, healthcare, and consumer goods, where it is used to produce a wide range of plastic components and parts.