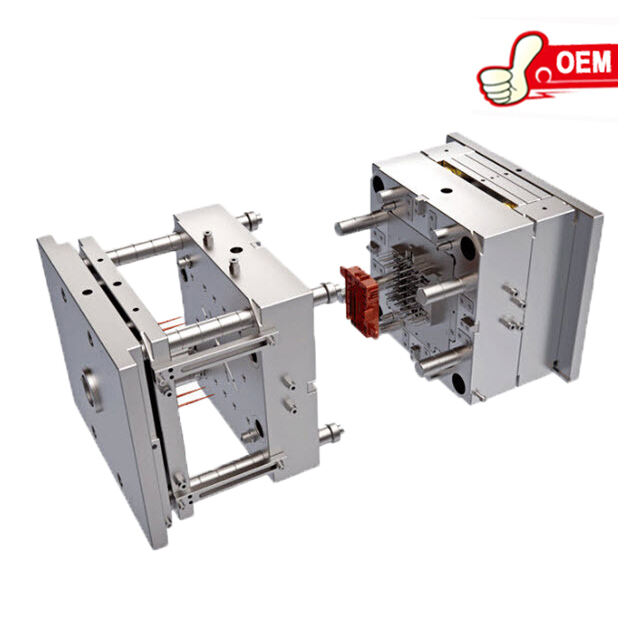

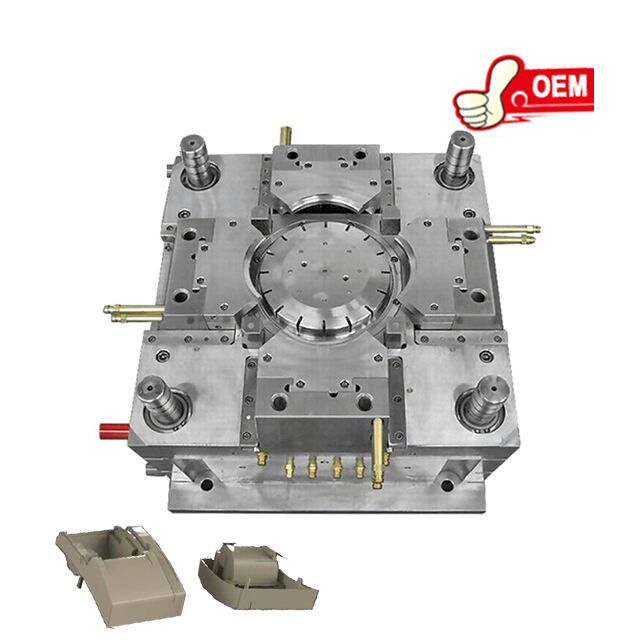

two plate injection mould

The two plate injection mould is a precision tooling system widely utilized in plastic manufacturing industries for producing high-volume, intricate plastic parts. Its main function is to shape molten plastic into the desired form through injection into a mould cavity. Technological features of the two plate injection mould include a robust design with two plates that come together to enclose the mould cavity, ensuring accurate part dimensions and complex geometries. These moulds are equipped with advanced temperature control systems, high-speed injection units, and automated ejection mechanisms. Such features make them ideal for applications ranging from automotive components and consumer electronics to medical devices and packaging materials, where precision and quality are paramount.