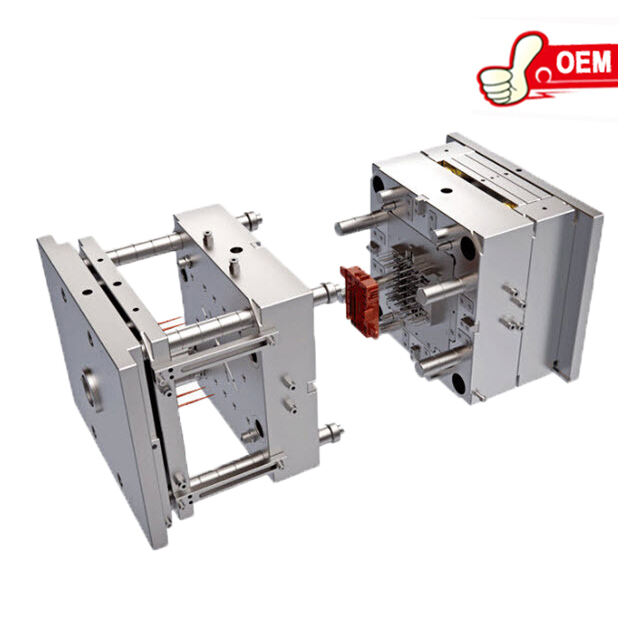

Precision Engineering for Consistency

One of the unique selling points of the plastic bucket mould is its high-precision engineering. This feature ensures that every plastic bucket that is produced has uniform dimensions and quality, which is critical for both branding and practical use. The precision extends to the threads, handles, and overall finish of the bucket, ensuring a seamless user experience. For manufacturers, this precision translates to fewer defects and rejections, ultimately leading to a more cost-effective production process and higher customer satisfaction.