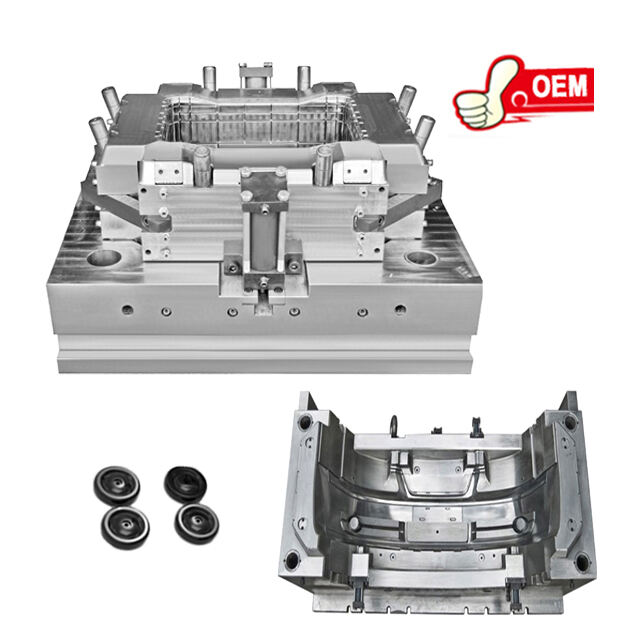

precision moulding and moulds

Precision moulding and moulds are integral components in the manufacturing industry, providing intricate shaping solutions for plastics, metals, and other materials. The main functions of precision moulding involve producing high-accuracy parts with intricate details through processes like injection moulding or die-casting. Technological features include the use of high-quality materials, precise engineering, and advanced CNC machining, ensuring superior durability and performance. These moulds find extensive applications across various industries such as automotive, electronics, medical, and consumer goods, where precision and consistency are paramount.