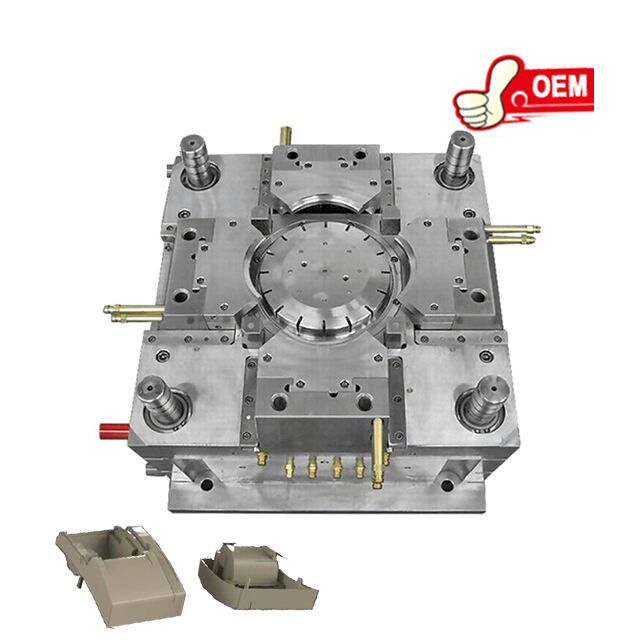

plastic mold fabrication

Plastic mold fabrication is a precision engineering process that involves the creation of molds used to shape and form raw plastic materials into finished products. The main functions of plastic molds are to give plastic parts their precise shapes, sizes, and structures. Technological features of mold fabrication include the use of advanced CAD/CAM software for design, high-speed CNC machining for precision cutting, and rigorous quality control measures to ensure the molds meet exact specifications. These molds are used across various industries, from automotive and electronics to healthcare and packaging, making them integral to modern manufacturing.