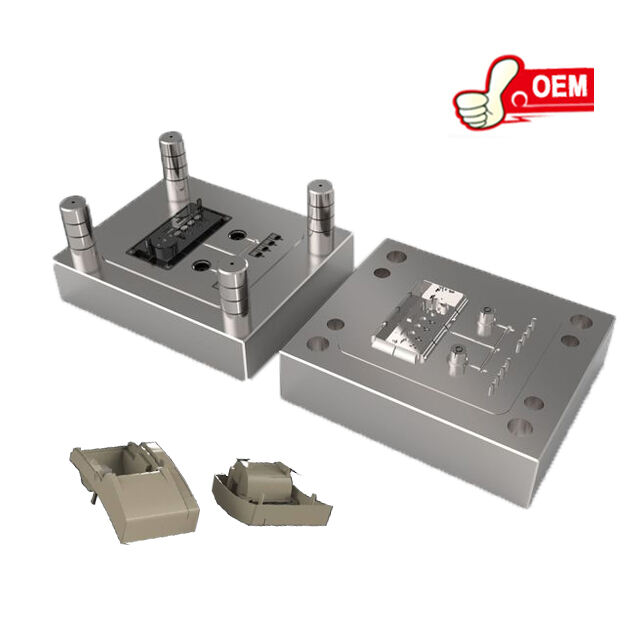

plastic moulding supplies

Plastic moulding supplies are integral components in the manufacturing process of plastic products. These supplies encompass a range of materials and tools necessary for the creation of precise and intricate plastic parts and components. The main functions of plastic moulding supplies include shaping, forming, and trimming of plastics to desired specifications. Technological features of these supplies include high durability, heat resistance, and the ability to maintain close tolerances, ensuring the production of high-quality and precise plastic items. Applications span various industries, from automotive and electronics to healthcare and consumer goods, as they are vital for producing everything from car parts to medical devices and everyday plastic items.