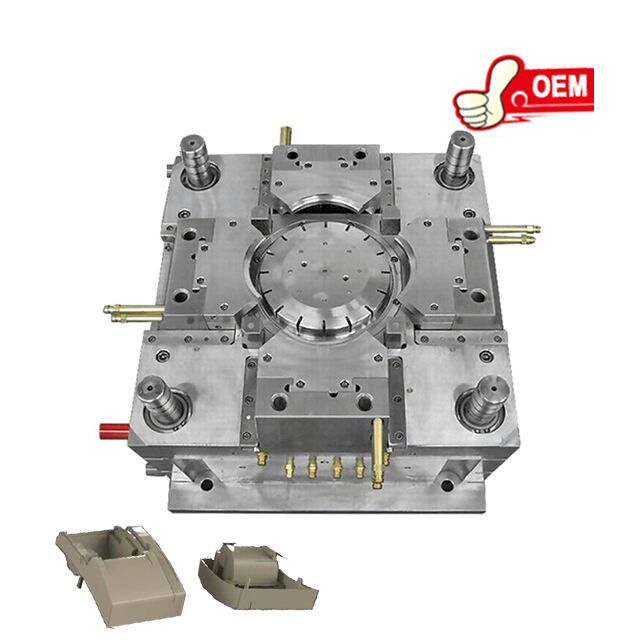

Material Versatility and Customization

The versatility of PVC as a material, combined with the precision of injection molding, allows for a high degree of customization at a reasonable PVC injection price. PVC can be formulated to have different physical properties, such as rigidity or flexibility, and can withstand a range of temperatures and chemical exposures. This means that whether a customer needs parts for automotive use, medical devices, or construction, the PVC injection molding process can deliver customized solutions that meet the specific requirements of these diverse applications.