molded plastics industries

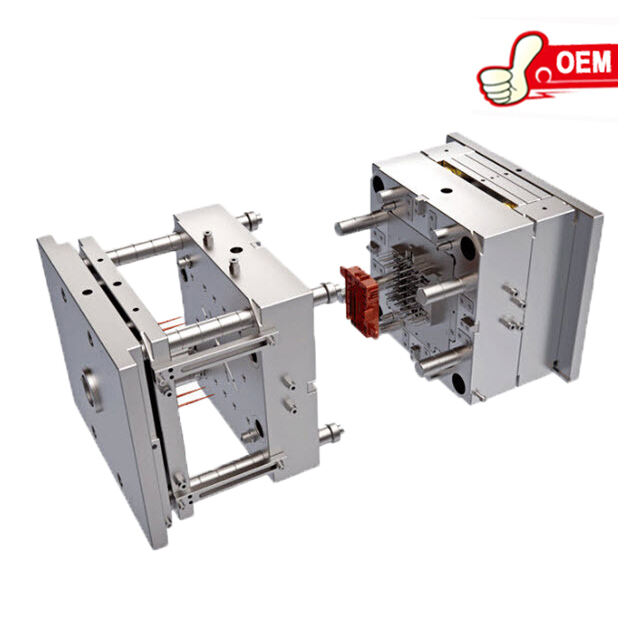

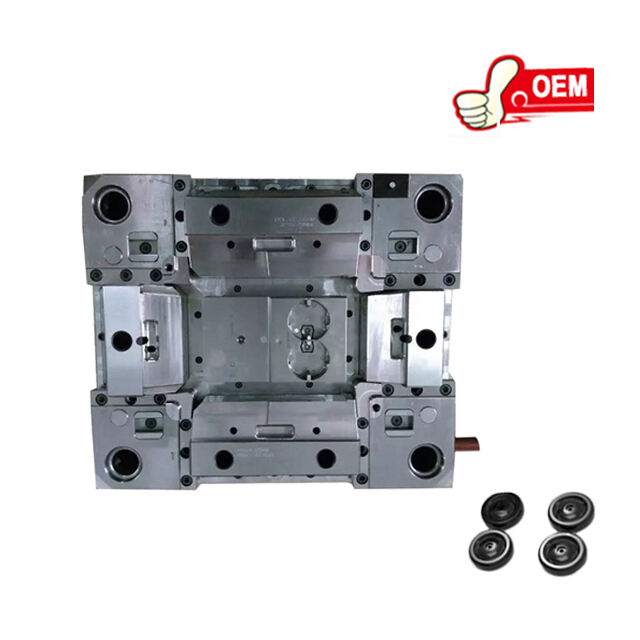

The molded plastics industry is a cornerstone of modern manufacturing, responsible for producing a vast array of plastic products through a highly efficient and precise process. The main functions of this industry involve the shaping of molten plastic materials into specific forms using molds, a process that includes injection molding, blow molding, and rotational molding among others. Technological features of the industry include advanced machinery, automated systems, and computer-aided design (CAD), which ensure high precision and consistency in the manufacturing process. Applications of molded plastics are extensive, ranging from automotive parts and consumer electronics to medical devices and packaging materials. These products are integral to numerous industries due to their durability, low cost, and design flexibility.