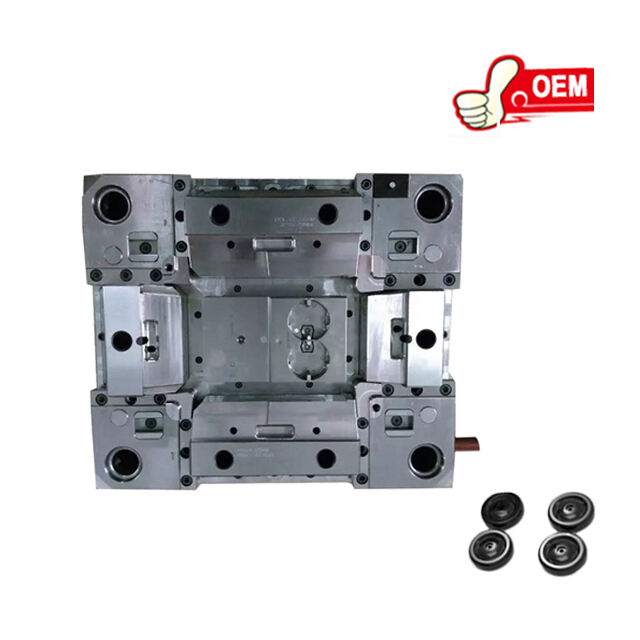

rapid tooling injection molding

Rapid tooling injection molding is a cutting-edge manufacturing process that streamlines the production of plastic parts. Its main functions include quickly producing high-quality molds and prototypes, allowing for faster iteration and testing of products. Technological features of rapid tooling include the use of advanced materials and precision machinery to create molds with fine details and complex geometries. This process also employs 3D printing and CNC machining to achieve precise mold dimensions. Applications of rapid tooling injection molding span across various industries, such as automotive, aerospace, medical, and consumer goods, where fast and cost-effective production of plastic components is crucial.