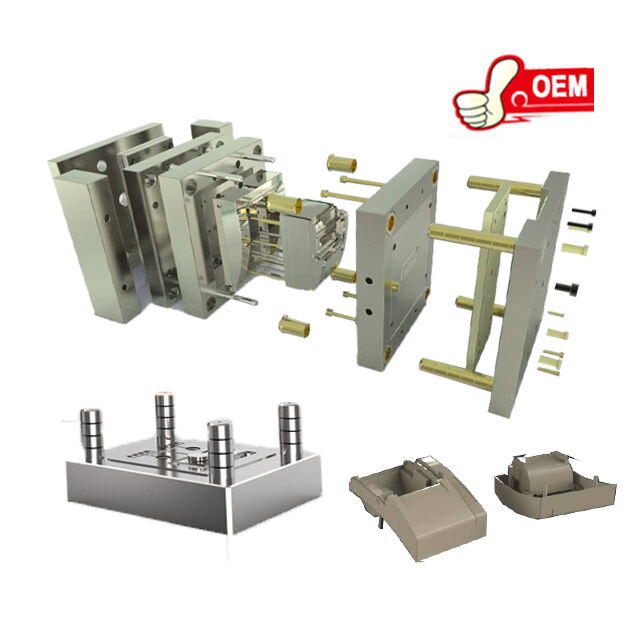

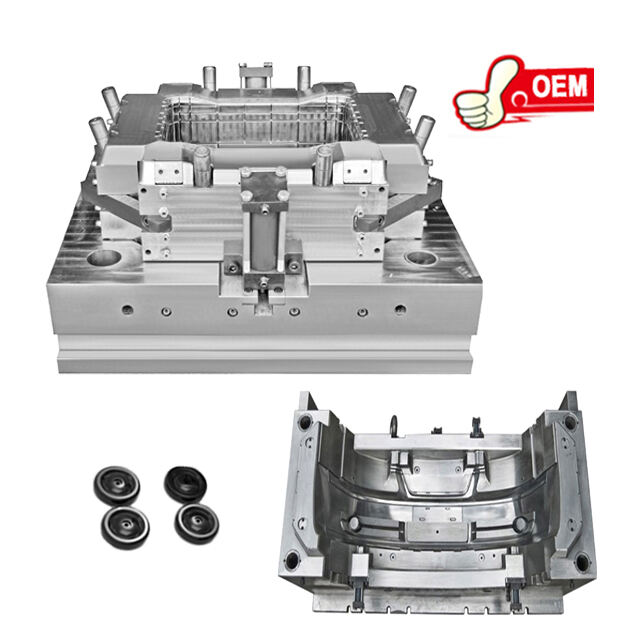

rubber injection molding companies

Rubber injection molding companies specialize in producing precision parts made from rubber through a sophisticated injection molding process. The main functions of these companies include the design, production, and quality control of rubber components. Utilizing advanced technology, they operate high-tech machinery that injects liquid rubber into a mold, where it solidifies to the desired shape. Key technological features include precise temperature control, automated systems, and the ability to produce complex geometries with high consistency. The applications of rubber injection molding are vast, ranging from automotive parts, medical devices, seals, gaskets, to consumer goods, reflecting the versatility and demand for this manufacturing process.