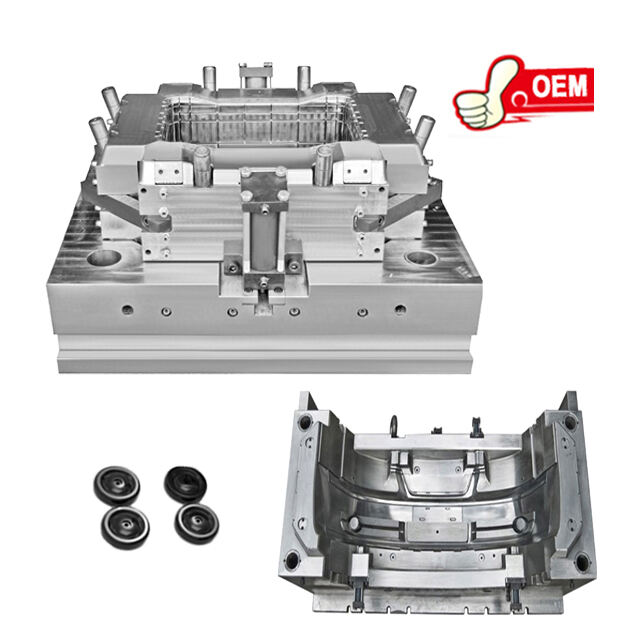

small injection molding

Small injection molding is a precision manufacturing process used to create small plastic parts and components. Its main functions include producing intricate designs with high precision and consistency, which is crucial for industries requiring complex, small-scale parts. Technological features of small injection molding machines include their compact size, faster cycle times, and the ability to use a variety of plastics. These machines are capable of producing parts with tight tolerances and can operate with minimal supervision. Applications of small injection molding are diverse, ranging from medical devices and electronics to automotive parts and consumer goods, where the demand for precise, high-quality, and small-scale components is significant.