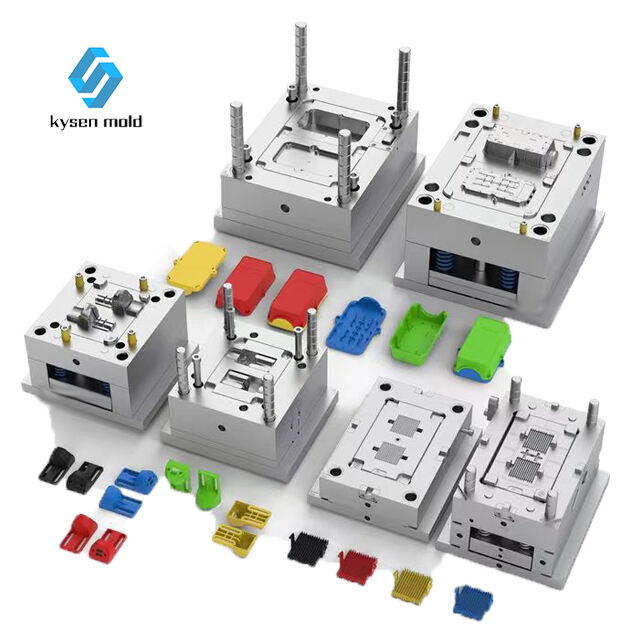

plastic mold casting

Plastic mold casting is a precision manufacturing process used to produce high-quality plastic components. Its main function is to accurately replicate the shape and details of a product design in plastic. This process involves heating the plastic material until it melts and then injecting it into a mold cavity, where it cools and solidifies to the desired form. Technological features of plastic mold casting include high accuracy, repeatable production, and the ability to create complex shapes and intricate details. This process is widely used across various industries, including automotive, electronics, healthcare, and consumer goods, for producing parts ranging from small components to large-scale items.