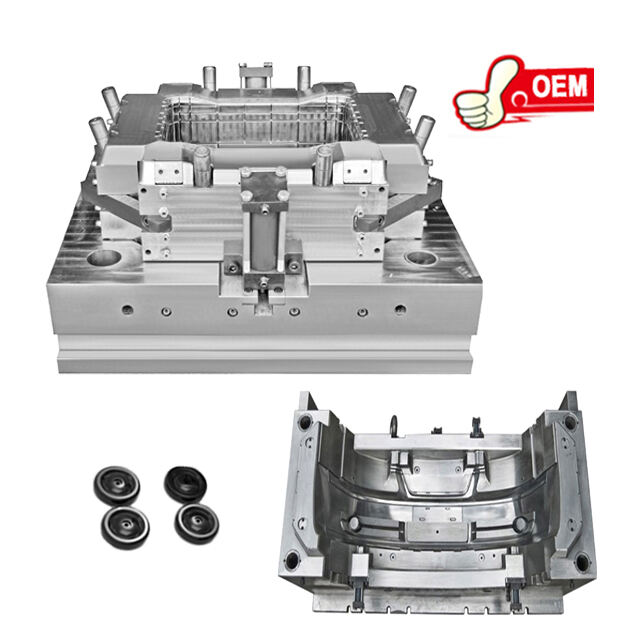

small run injection molding

Small run injection molding is a specialized manufacturing process that allows for the production of small quantities of plastic parts with high precision and quality. Its main functions include creating intricate designs, producing parts with tight tolerances, and enabling rapid prototyping and production. Technological features of small run injection molding include the use of advanced injection molding machines, which are capable of precise control over temperature, pressure, and speed, ensuring consistent quality across all parts. This process is ideal for applications where low-to-medium volume production is required, such as in the medical, aerospace, and consumer electronics industries.