vertical injection molding

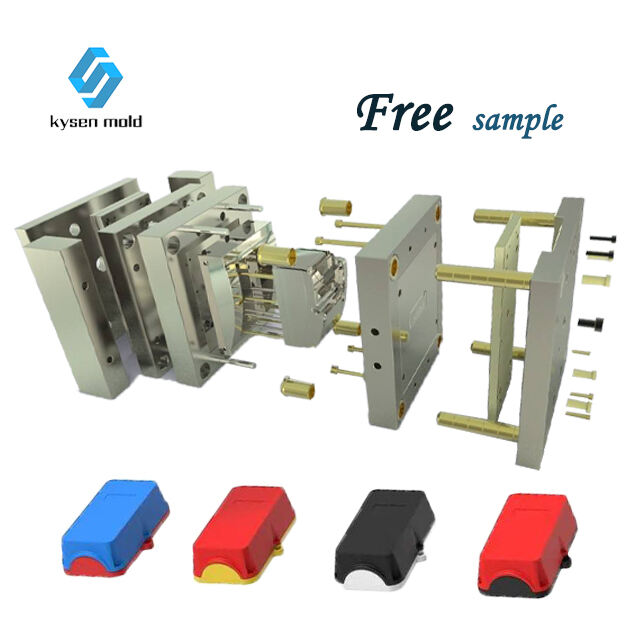

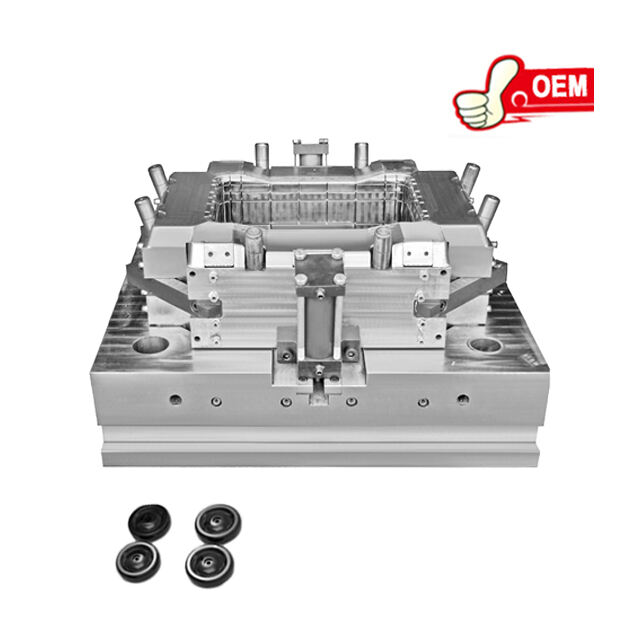

Vertical injection molding is a sophisticated manufacturing process used to create plastic parts by injecting molten material into a mold. Its main functions include producing precision parts with high accuracy and consistency. Technological features of vertical injection molding machines include a vertical clamping force and injection system, which allows for efficient use of space and automation capabilities. These machines are equipped with advanced control systems that monitor and regulate temperature, pressure, and speed for optimal molding conditions. Applications of vertical injection molding span across various industries, from automotive and medical to consumer goods and electronics, where complex and intricate parts are required.