Contact Info

NO 377, Luchang Road, Kunshan, Suzhou

New York.

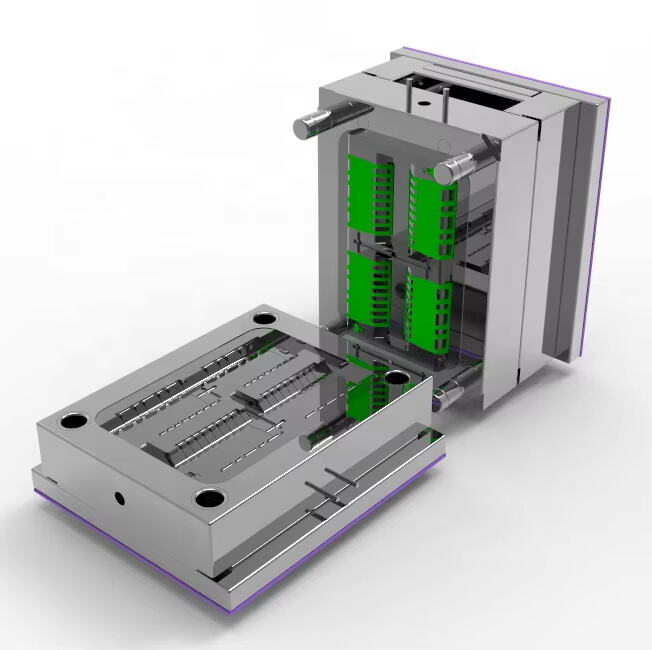

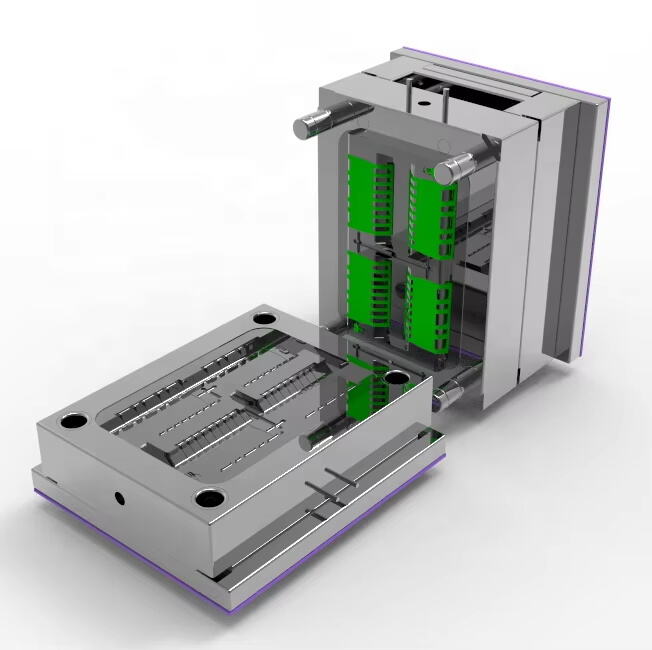

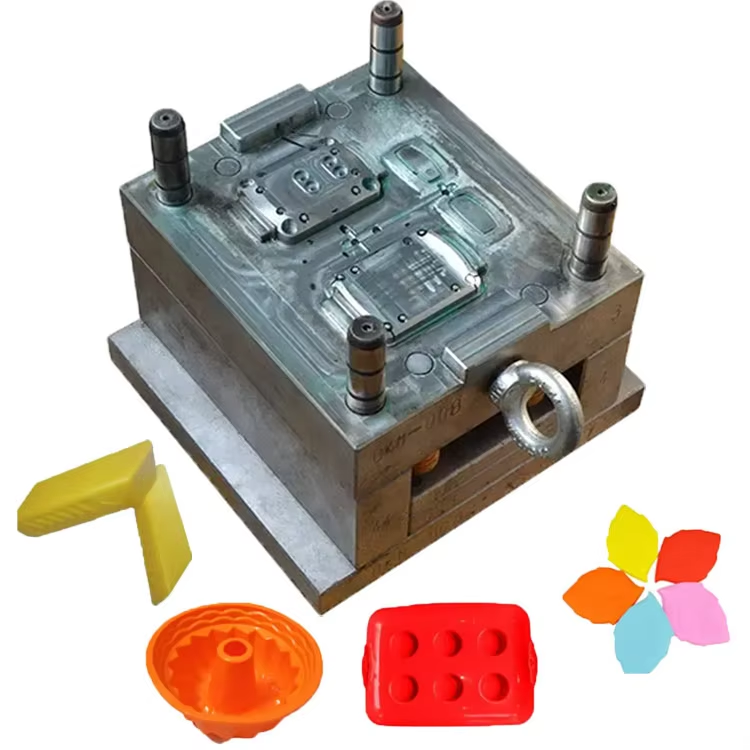

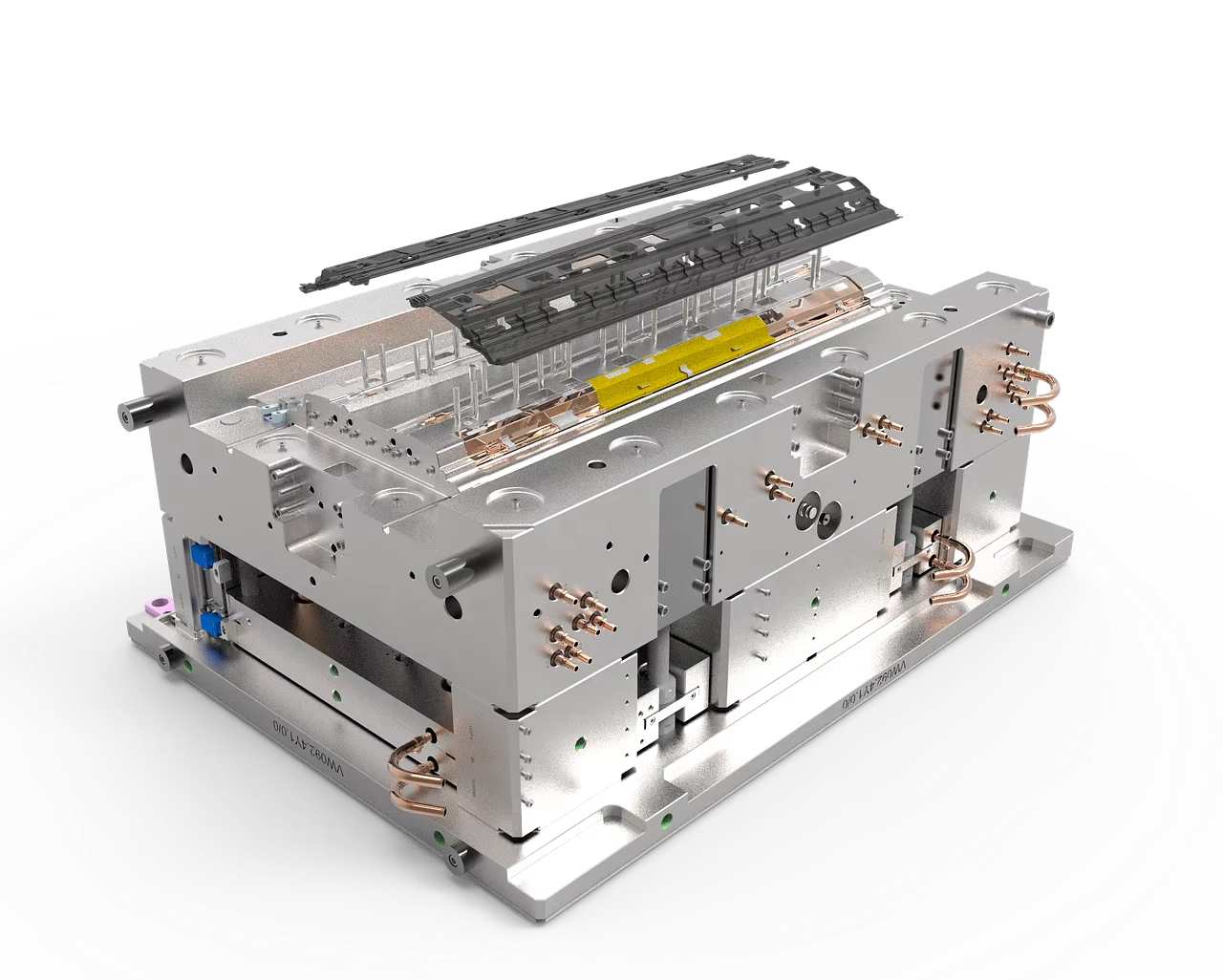

Overview of Plastic Injection Molds Plastic injection molds play a pivotal role in modern manufacturing by enabling the rapid and cost-effective production of complex plastic parts. These molds are integral to various industries, including automotiv...

VIEW MORE

Understanding the Importance of Material Selection in Injection Moulding Material selection is a cornerstone in injection moulding, significantly affecting the final product's quality and performance. Different materials offer varying mechanical pro...

VIEW MORE

Understanding Warpage in Injection Molding Warpage in injection molding refers to the distortion that occurs in molded parts during or after production, primarily due to uneven cooling and material properties. This issue often arises when the coolin...

VIEW MORE

Cycle time in injection molding refers to the total time required to produce a single part, from mold closing to part ejection. It directly impacts production efficiency by determining output rates. Identifying factors that influence cycle time allow...

VIEW MORE

Injection molding often produces flawed parts, but you can fix these issues with the right approach. Understanding the causes of common defects helps you make necessary adjustments. By addressing these problems, you improve product quality and reduce...

VIEW MORE

Injection molding relies on a wide range of materials to create durable and functional products. Thermoplastics dominate due to their flexibility and ease of use. You’ll often encounter common materials like ABS, polypropylene, and nylon. Choos...

VIEW MORE

In 2025, the demand for durable and precise plastic parts will continue to grow. You must focus on producing parts that meet strict performance standards. The quality of plastic parts ensures reliability in industries like automotive, healthcare, and...

VIEW MORE

Creating a plastic injection mold takes time, depending on its complexity and size. Simple molds can be ready in just a few weeks. Complex designs, however, may require months. Material availability and design precision also play a role. By understan...

VIEW MORE

Introduction The cost of a plastic injection mold depends on multiple factors that directly influence its pricing. Material selection plays a significant role, as different materials vary in durability and expense. Design complexity also impacts the ...

VIEW MORE

Cost efficiency plays a vital role in injection molding. It allows you to stay competitive in manufacturing while maintaining high-quality production. By reducing unnecessary expenses, you can allocate resources more effectively and improve overall p...

VIEW MORE

Polypropylene (PP) and Polyethylene (PE) stand out as the most affordable options for injection molding. These plastics offer you a perfect combination of low cost, flexibility, and ease of processing. Their widespread use in various industries highl...

VIEW MORE

Polypropylene (PP) stands out as the most widely used injection molding material. Its versatility allows you to create durable and lightweight products for various industries. You can rely on its affordability to keep production costs low without com...

VIEW MORE