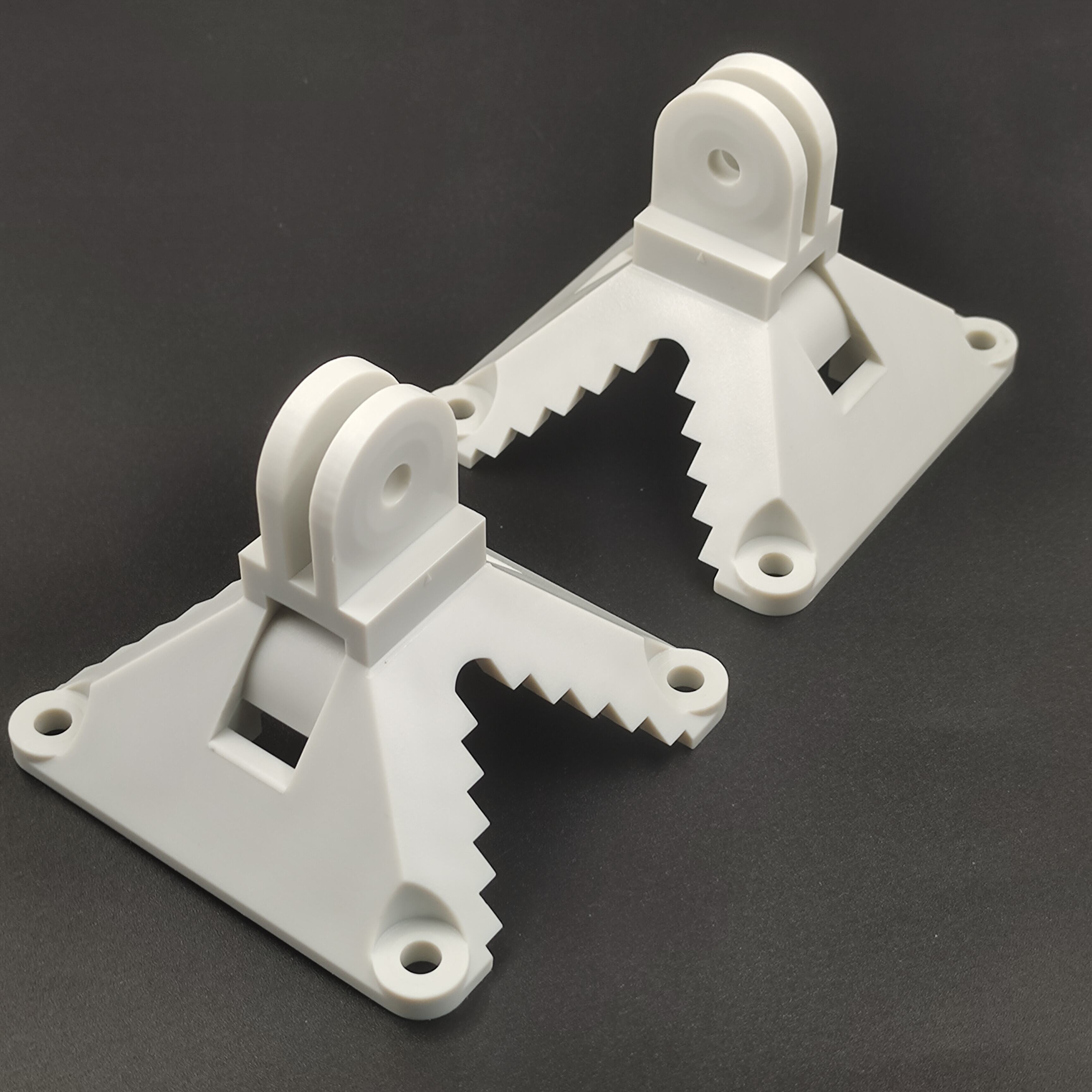

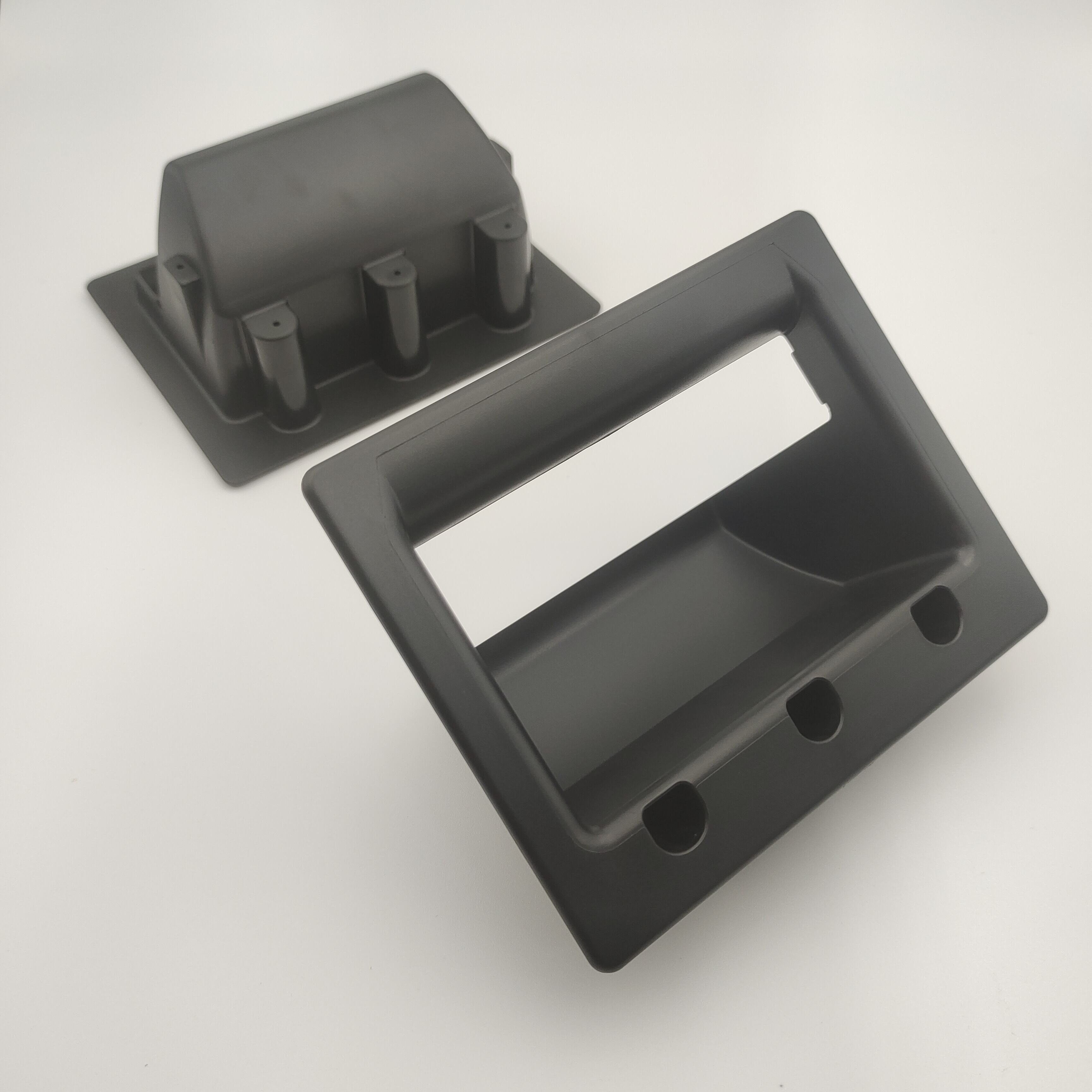

automotive plastic injection moulding

Automotive plastic injection moulding is a sophisticated process integral to the automotive industry. It involves injecting molten plastic into a mould to form intricate parts and components, which serve a variety of functions within vehicles. The main functions include producing exterior body parts, interior trims, and under-the-hood components that are both functional and aesthetically pleasing. Technological features of this process encompass high-precision machinery, computer-aided design, and robust control systems that ensure the manufacturing of parts with tight tolerances and consistent quality. Its applications are widespread, from automotive lighting to dashboard assembly, making vehicles lighter, more fuel-efficient, and cost-effective to produce.