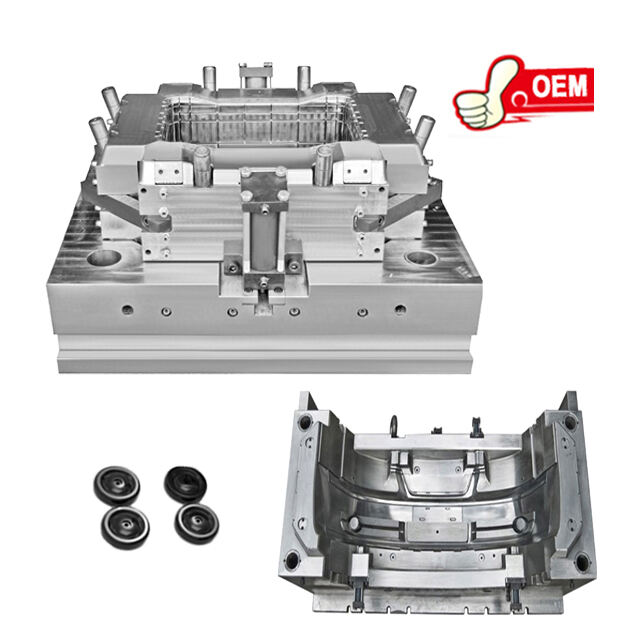

billion injection moulding

The billion injection moulding is a sophisticated technology designed to produce high volumes of identical plastic parts efficiently and precisely. This process involves melting plastic material, which is then injected under pressure into a mould cavity, where it cools and solidifies to the desired shape. The main functions include high-speed production, intricate design capabilities, and consistent quality control. Technological features include automated systems, temperature control, and advanced robotics, ensuring precision and reliability. Applications span across various industries, such as automotive, electronics, medical, and consumer goods, making it an indispensable manufacturing solution for a multitude of products.