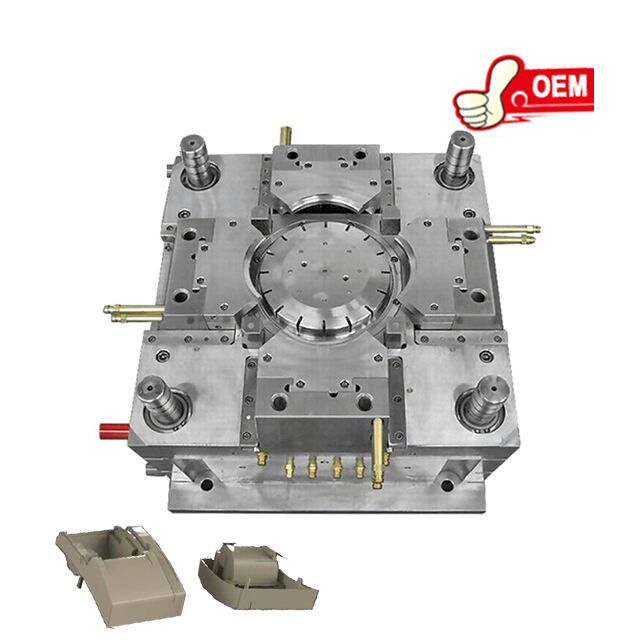

cheap custom injection molding

Cheap custom injection molding is a cost-effective manufacturing process that involves producing parts by injecting molten material into a mold. Its main function is to create precise and intricate plastic components quickly and affordably. Technological features include the use of advanced injection molding machines that ensure high precision and consistency in part production. These machines can handle a variety of materials, such as polycarbonate, polypropylene, and ABS. The applications of cheap custom injection molding are vast, ranging from automotive parts and medical devices to consumer goods and electronics. This process is ideal for both small-scale production runs and large-scale manufacturing, offering flexibility and scalability for businesses.