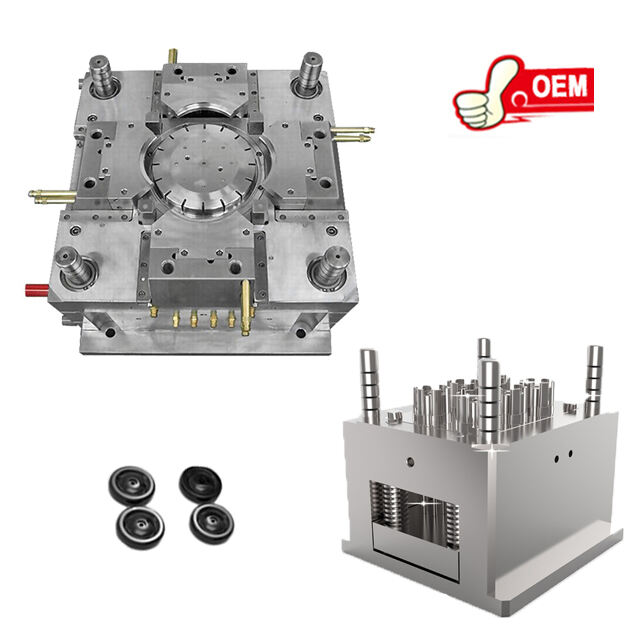

custom mold plastic injection

Custom mold plastic injection is a sophisticated manufacturing process that involves producing plastic parts by injecting molten material into a mold cavity. The main functions of this process include shaping, forming, and fabricating plastic products to precise specifications. Technological features such as computer-aided design (CAD) and precision engineering enable the creation of intricate molds suitable for a wide range of applications. The process is highly automated, ensuring consistent quality and high production rates. Common applications of custom mold plastic injection include automotive parts, consumer electronics, medical devices, and household goods, among others.