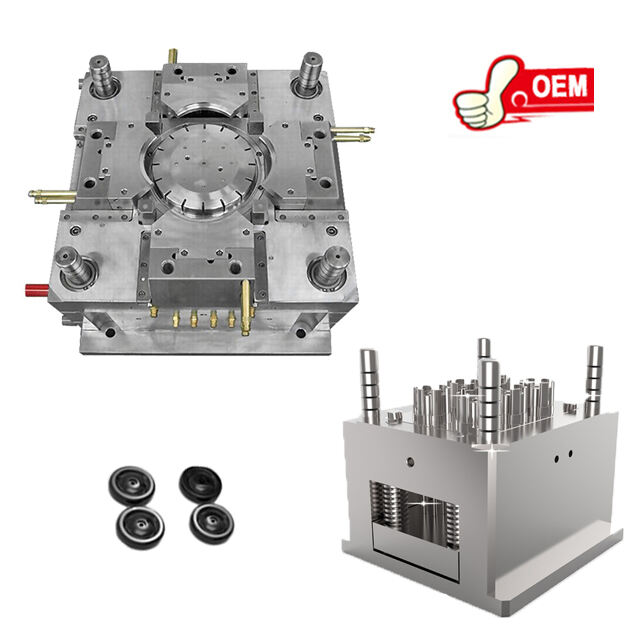

mold your own plastic parts

The mold your own plastic parts is a sophisticated piece of technology designed for efficiency and precision in the manufacturing of plastic components. Its main function is to shape molten plastic into desired forms using a carefully crafted mold. The technological features include a durable steel construction, high-precision engineering, and automated temperature control systems that ensure consistent quality in the molding process. These molds are versatile, capable of producing a wide range of parts from simple to complex geometries, and are used across various industries including automotive, electronics, and consumer goods.