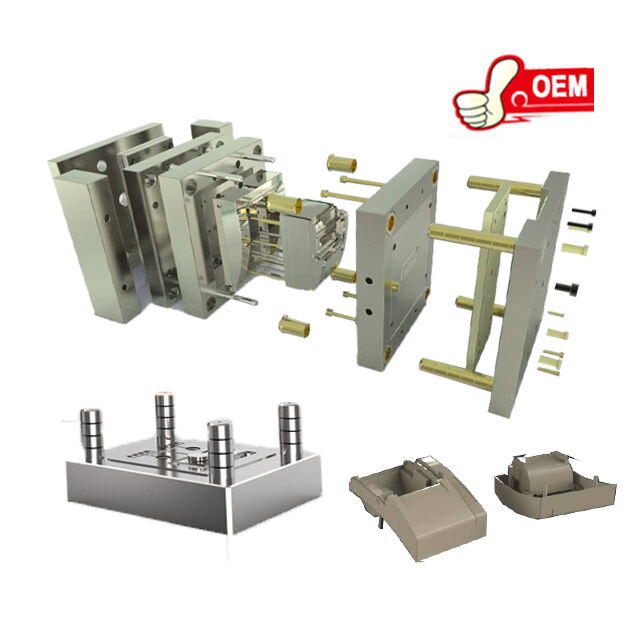

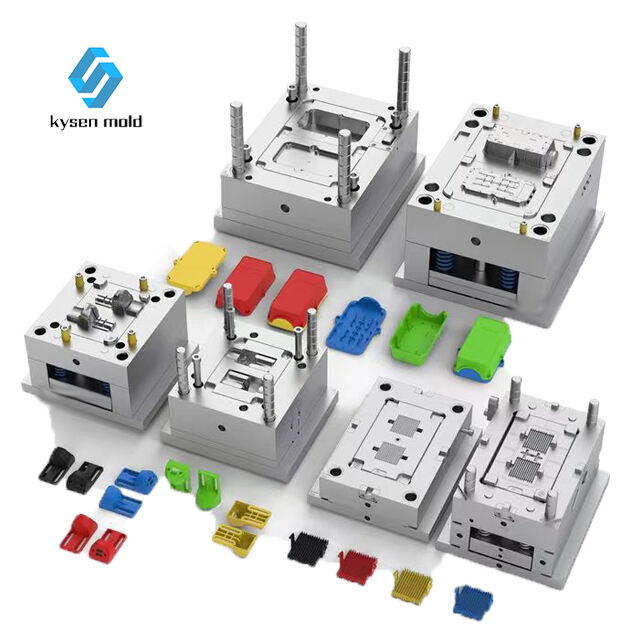

custom injection molded plastic parts

Custom injection molded plastic parts are precision-engineered components that serve a variety of functions across industries. These parts are designed with intricate details and can perform complex tasks due to their precise measurements and high tolerance levels. Technological features include the use of advanced polymers, which are selected for their specific properties to match the demands of the application. The injection molding process allows for the creation of complex shapes, uniformity, and the integration of multiple functions within a single part. These components are integral in industries such as automotive, medical, electronics, and consumer goods, where functionality and reliability are paramount.