hand injection molding

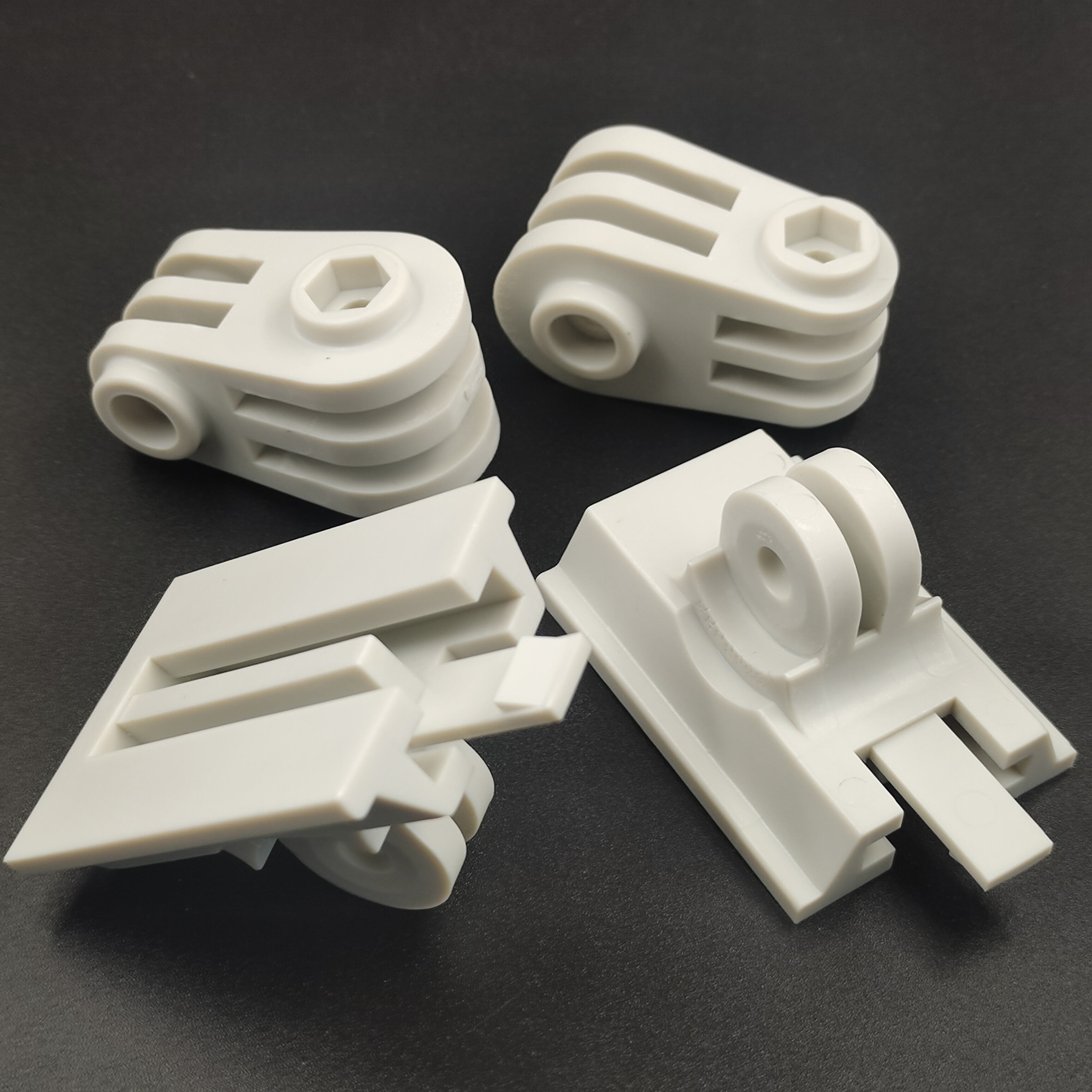

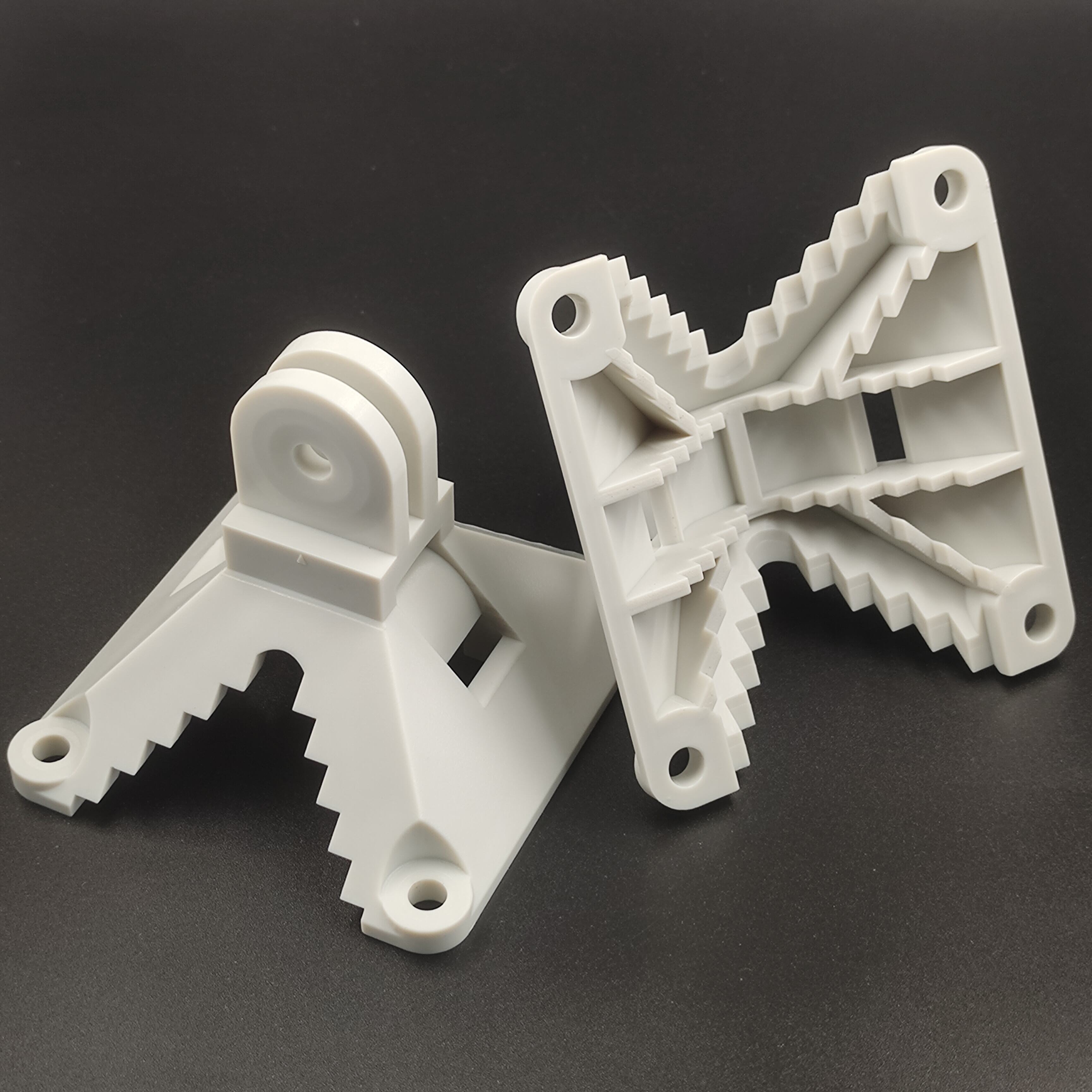

Hand injection molding is a precision manufacturing process used to produce plastic parts by injecting molten material into a mold cavity. Its main functions include shaping, forming, and cooling the plastic until it solidifies into the desired product. Technological features of hand injection molding machines encompass manual operation, which allows for flexibility in production, and the ability to produce small to medium-sized batches of parts with high precision. These machines are equipped with heated barrels and injection units that ensure consistent material flow and quality. Applications of hand injection molding are vast, ranging from medical devices and automotive components to consumer goods and electronics, making it a versatile solution for various industries.