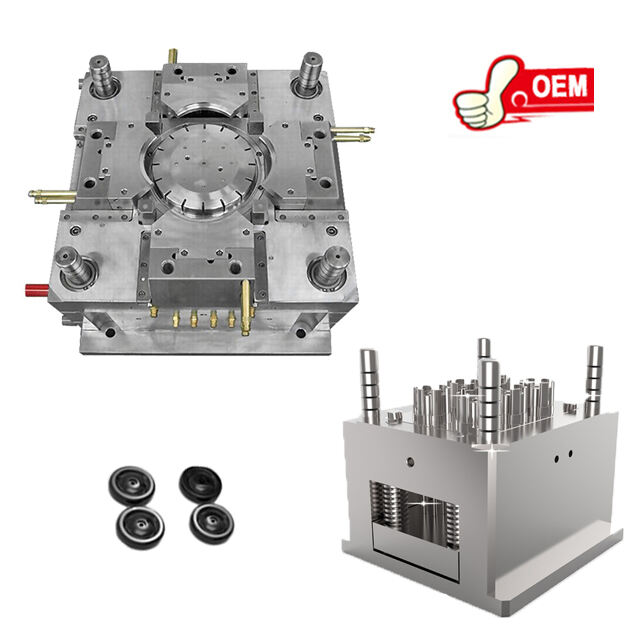

low cost plastic injection molding

Low cost plastic injection molding is a highly efficient process for producing plastic parts by injecting molten material into a mold cavity. Its main functions include shaping, forming, and producing intricate details in plastic components. Technological features such as precision molds, automated systems, and fast cycle times ensure high-volume production at minimal costs. This process is versatile, capable of producing a wide range of products from small medical devices to large automotive parts. The use of advanced materials and design software enhances efficiency and precision, making it a preferred choice for industries requiring high-quality plastic parts at a low cost.