quick injection molding

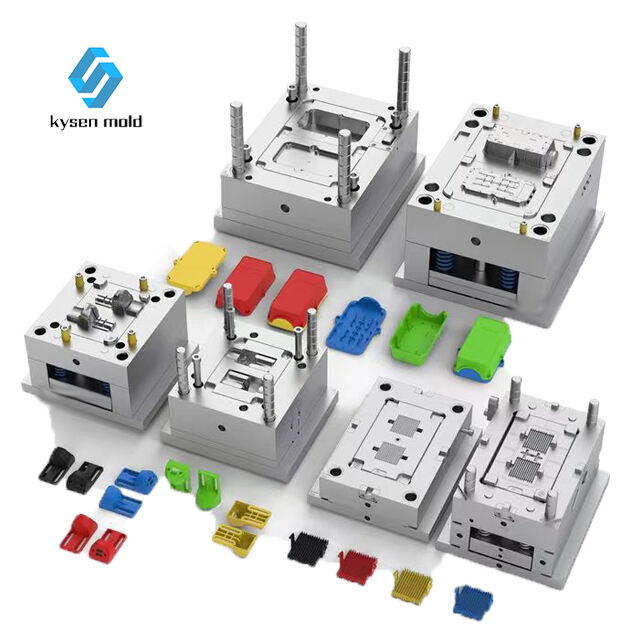

Quick injection molding is an innovative technique that streamlines the production of plastic parts by significantly reducing the lead time required for mold creation. Its main functions include rapid prototyping and low-volume manufacturing, enabling businesses to accelerate their product development cycles. Technological features of quick injection molding encompass the use of specialized materials and advanced mold-making processes that facilitate faster cooling and curing. This approach is particularly beneficial for intricate designs and complex geometries. Applications span across various industries, from automotive and electronics to healthcare and consumer goods, where speed and precision are critical.