small volume injection molding

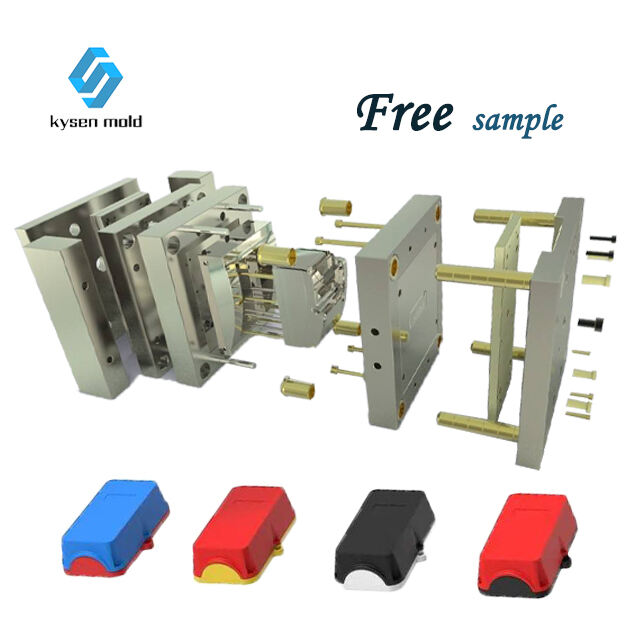

Small volume injection molding is a specialized manufacturing process that involves producing small quantities of plastic parts using injection molds. Its main functions include creating intricate designs, ensuring high precision, and facilitating rapid prototyping. Technological features of small volume injection molding include the use of advanced machinery, precise mold-making techniques, and the ability to work with a wide range of materials. This process is ideal for industries that require customized, small-batch production such as medical devices, electronics, and automotive components. With its versatility and precision, small volume injection molding offers a cost-effective solution for businesses looking to produce high-quality plastic parts in limited quantities.