metal injection molding companies

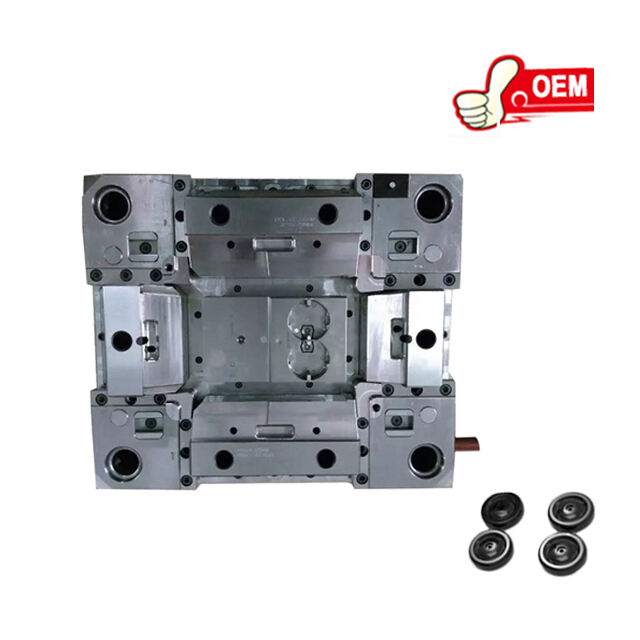

Metal injection molding companies specialize in the production of precision-engineered metal parts through a sophisticated process that combines the principles of plastic injection molding with powdered metal technology. These companies excel in creating complex shapes and geometries that are difficult to achieve with traditional metalworking methods. The main functions include the ability to produce parts in large volumes with high consistency and accuracy. Technological features of metal injection molding encompass the use of advanced machinery, robotics, and computer controls to ensure precision and efficiency. The applications span across various industries, such as automotive, medical, aerospace, and electronics, where intricate, high-performance metal components are in demand.