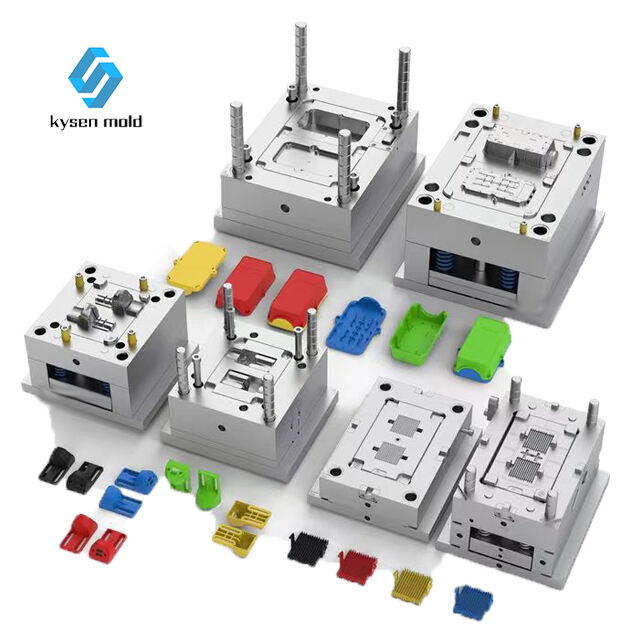

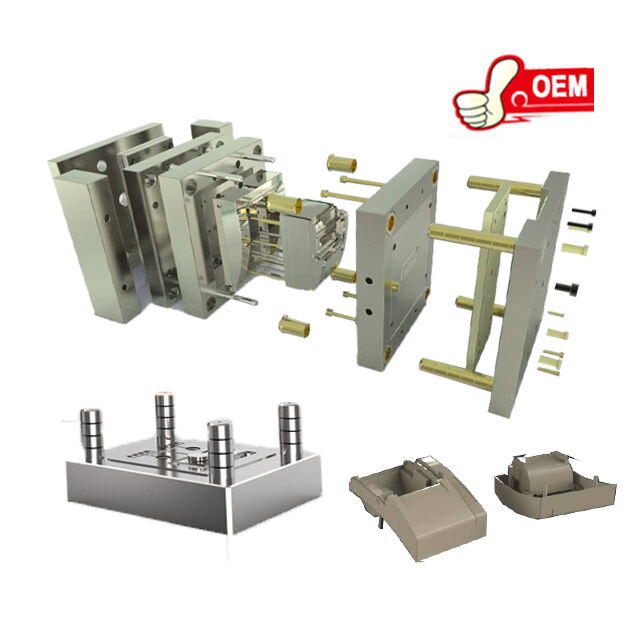

custom molded plastic containers

Custom molded plastic containers are precision-engineered solutions designed to meet specific storage and transportation needs. These containers are crafted with intricate molds to ensure they fit the exact dimensions and requirements of various products. Main functions include protection, organization, and preservation of goods during shipping and storage. Technological features such as reinforced walls, snap-on lids, and stacking capabilities enhance their utility. These containers find applications across industries such as healthcare, automotive, electronics, and retail, providing a durable and efficient way to manage inventory and maintain product integrity.